CPE Waterproof Board

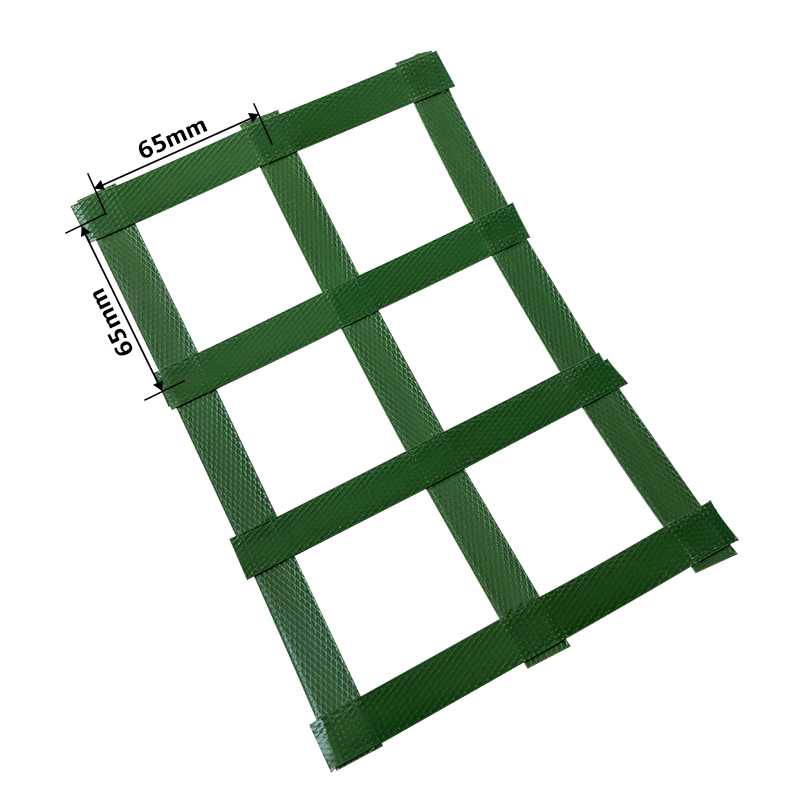

Chlorinated Polyethylene (CPE) waterproof board is a new type of high-strength polymer waterproofing material specifically designed for roads and bridges. This product uses chlorinated polyethylene as its base material, supplemented with modifiers, anti-aging agents, accelerators, and various reinforcing agents. It is refined through the processes of mixing and kneading, calendering, and double-sided compositing.

PRODUCT DETAILS

Core features:

✅High performance:High tensile strength (≥ 18Mpa), super strong elongation at break (≥ 600%), puncture resistance (300-600N), tear resistance (≥ 95N/m).

✅Durability:Excellent weather resistance (-35 ℃ low-temperature bending), oil resistance, flame retardancy, alkali resistance, and stable performance after thermal aging (tensile strength ≥ 15Mpa).

✅Convenient construction:Cold construction technology, easy to operate, not limited by climate.

✅Reliable Waterproof:0.3Mpa water pressure is impermeable for 24 hours.

Applicable scenarios:

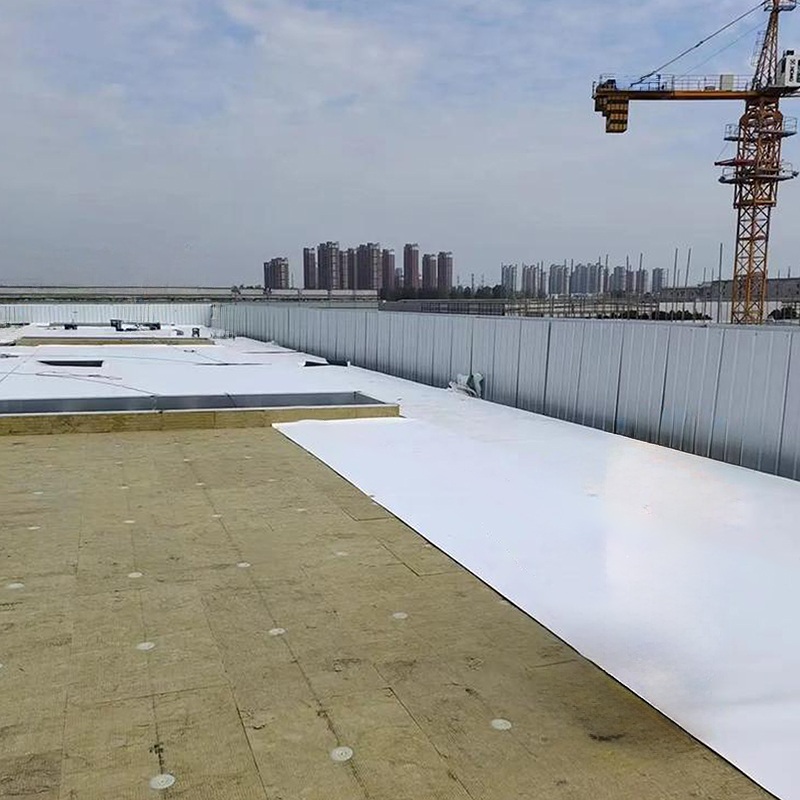

Infrastructure projects:Waterproofing of concrete bridge decks for highways, railway bridges, and culverts.

Building waterproofing:Industrial/civil building roofs, basements, and civil air defense engineering.

Water conservancy facilities:Reservoir, water tank, channel, sewage treatment system.

Industrial applications:Waterproof and anti-seepage measures for beam factories and large facilities.

Product specifications and performance parameters

Project

Specifications

1.5mm

2.0mm

2.5mm

3.0mm

Puncture strength (N)

300

400

500

600

Tensile elongation at break (%)

≥600

Tear strength k (N/m)

≥95

Low temperature bendability (℃≤)

-35

Tensile strength (Mpa)

≥18

Impermeability (0.3Mpa, 24h)

no-leakage

Heating expansion amount (mm)

extend

≤2

contract

≤6

Hot air aging (80 ℃ × 168h)

Tensile strength (Mpa)

≥15

Tensile elongation at break (%)

≥550

Alkali

Tensile strength (Mpa)

≥16

Tensile elongation at break (%)

≥550

Artificial climate change

Tensile strength (Mpa)

80

Tensile elongation at break (%)

70