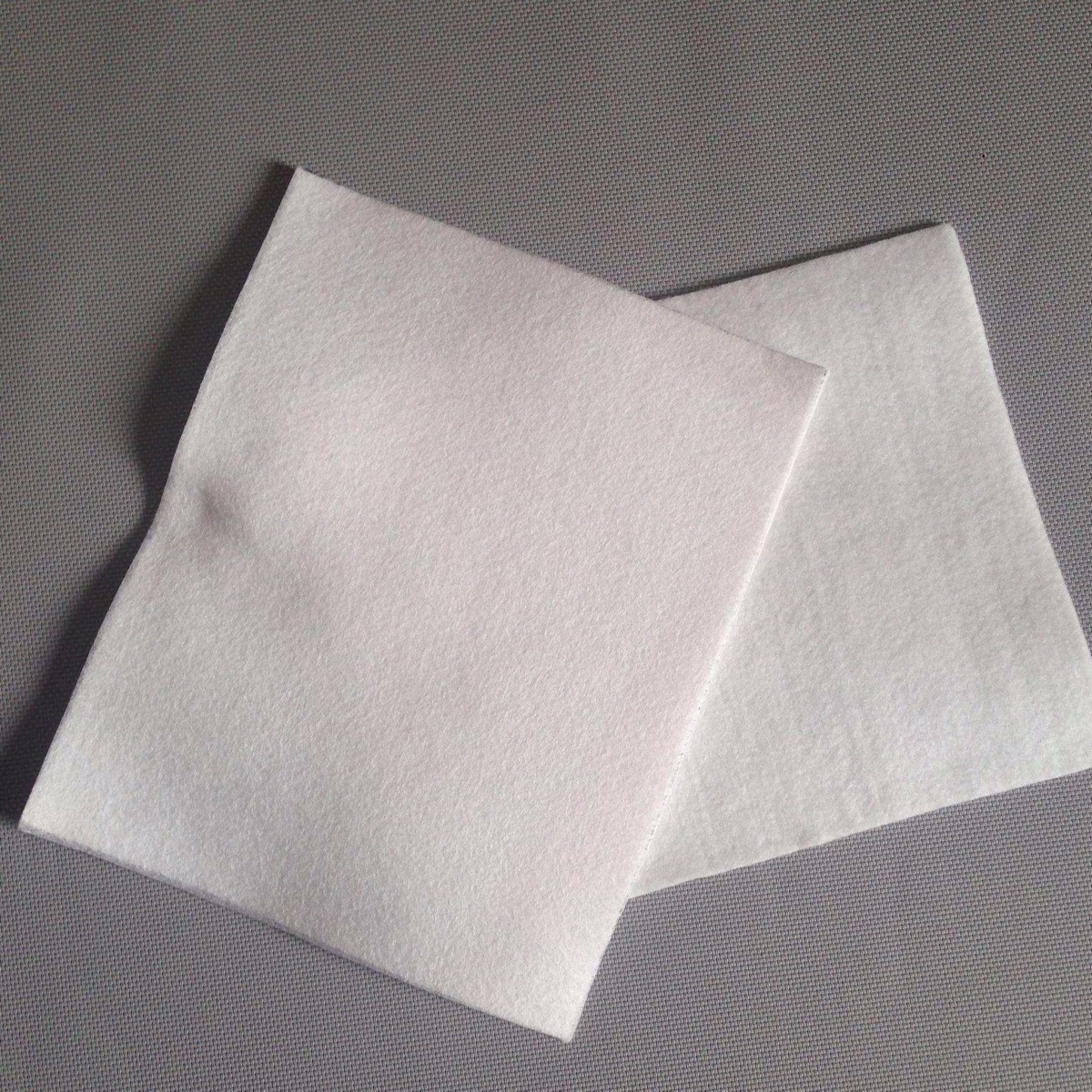

Staple Fiber Needle Punched Nonwoven Geotextiles

Geotextile is a permeable geosynthetic material made from synthetic fibers that are needle punched or woven. Short fiber needle punched nonwoven geotextile is one of the new materials of geosynthetic materials, with end products in the form of cloth. Geotextiles are divided into woven geotextiles and non-woven filament geotextiles.

PRODUCT DETAILS

Application scope: Staple Fiber Needle Punched Nonwoven Geotextile is a widely used geosynthetic material. Widely used for reinforcement of railway subgrade, maintenance of highway pavement, sports hall, dam protection, isolation of hydraulic structures, tunneling, coastal mudflat, reclamation, environmental protection and other projects.

Product performance

1. Utilize the good breathability and permeability of geotextiles to allow water flow through, thereby effectively intercepting sand loss.

2. Geotextiles have good water conductivity and can form drainage channels with the interior of the soil to discharge excess liquids and gases from the soil structure.

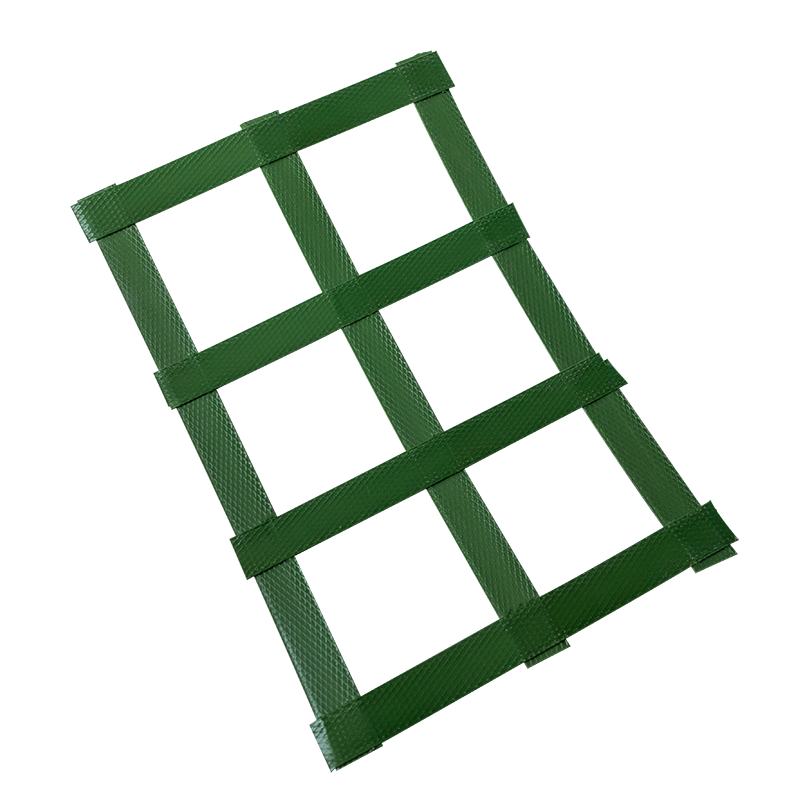

3. Utilize geotextiles to enhance the tensile strength and deformation resistance of soil, improve the stability of building structures, and improve soil quality.

4. Effectively diffuse, transmit or decompose concentrated stress to prevent soil from being damaged by external forces.

5. Prevent mixing between upper and lower layers of sand, gravel, soil, and concrete.

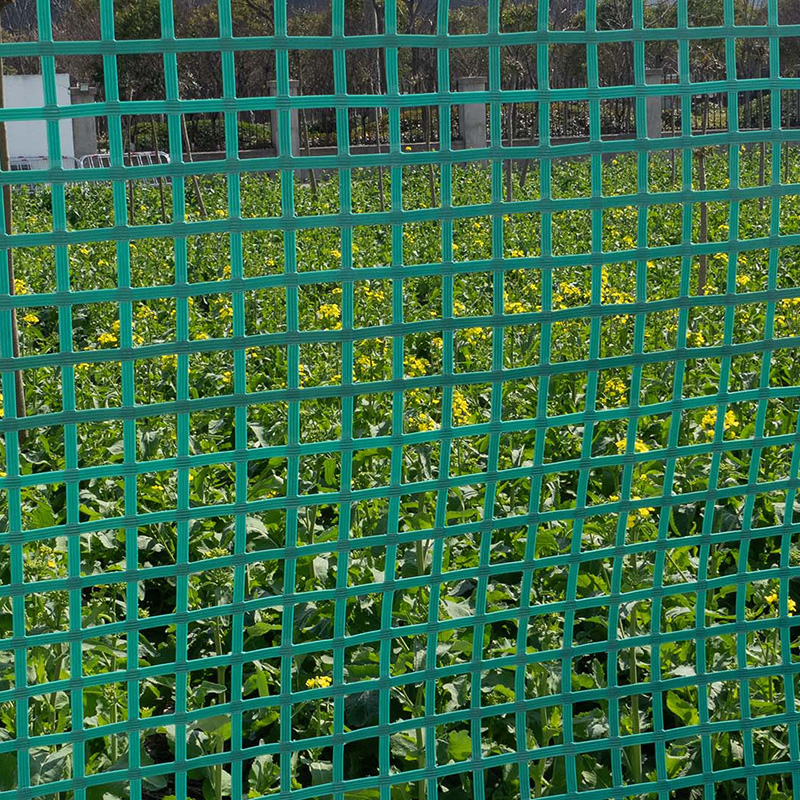

6. The mesh is not easily blocked - the mesh structure formed by amorphous fiber tissue has strain and mobility.

7. High permeability - able to maintain good permeability under soil water pressure.

8. Corrosion resistance - made from synthetic fibers such as polypropylene or polyester, acid and alkali resistant, non corrosive, insect and frog resistant, and antioxidant.

9. Simple construction - lightweight, easy to use, and easy to construct.

Project/Performance/Specifications | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | remarks |

Deviation in unit area quality (%) | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 | — |

Thickness mm ≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | — |

Width deviation% | -0.5 | — | ||||||||||

Breaking strength KN/m ≥ | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11.0 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | Vertical and horizontal directions |

Fracture elongation rate ≤ (%) | 25~100 | |||||||||||

CBR breaking strength Kn ≥ | 0.3 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 | — |

Equivalent aperture 090095)mm | 0.07-0.2 | — | ||||||||||

Vertical permeability coefficient cm/s | Kx(10-1-10-3) | K=1.0-9.9 | ||||||||||

Tear strength Kn ≥ | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.60 | Vertical and horizontal directions |