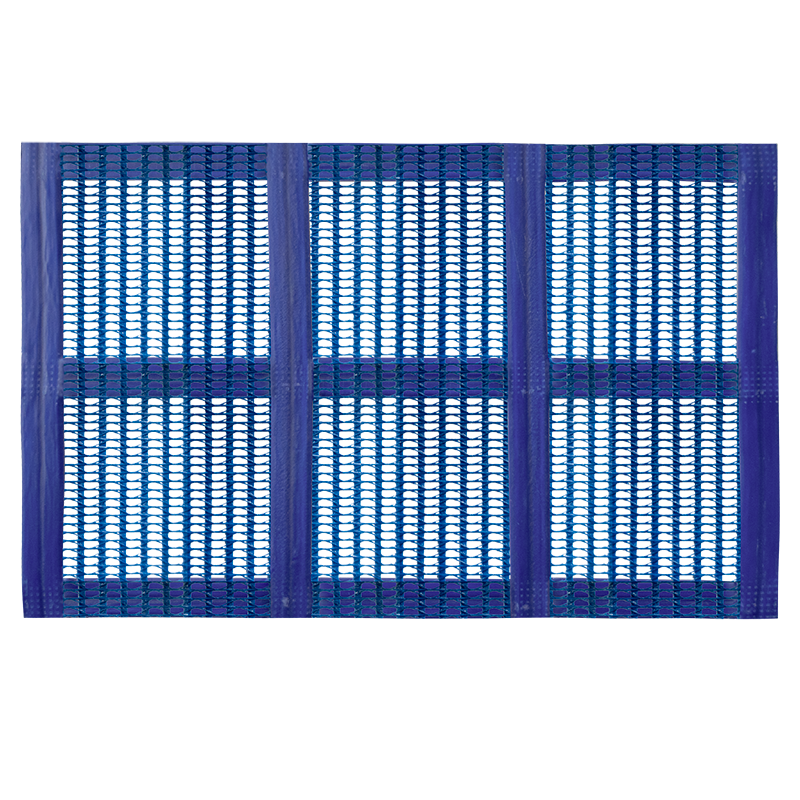

Long Filament Nonwoven Geotextile

Long Filament Nonwoven Geotextile is a new type of building material, made from synthetic fibers of high molecular weight polymers such as polyester, polypropylene, acrylic, and nylon. Long filament spunbond needle punched geotextile has multiple functions such as anti-seepage, filtration, drainage, isolation, reinforcement, protection, and sealing. Compared with conventional masonry and concrete materials, it has the advantages of low investment, simple construction process, short construction period, good anti-seepage effect, and high effective utilization coefficient of channels.

PRODUCT DETAILS

Application scope

Long Filament Nonwoven Geotextiles have good mechanical properties, as well as good longitudinal and transverse drainage performance, good elongation performance, and high chemical stability properties such as biological, acid and alkali resistance, and aging resistance. At the same time, it also has a wide range of pore sizes, a tortuous pore distribution, excellent permeability and filtration performance. Polyester filament geotextile has been widely used in the field of infrastructure construction and gradually applied to a wider range of fields.

Product Features

Geotextile has high strength. Due to the use of plastic flat wires, it can maintain sufficient strength and elongation in both dry and wet conditions, and is corrosion-resistant. It can withstand corrosion for a long time in soil and water with different acidity and alkalinity. Its permeability is good because there are gaps between the flat wires, so it has good water permeability. Long filament geotextile is a geosynthetic material used in geotechnical and civil engineering. It is made by networking and consolidating polyester filaments, and its fibers are arranged into a three-dimensional structure. In addition to having good mechanical properties, it also has good longitudinal and transverse drainage performance, good elongation performance, and high chemical stability such as biological, acid and alkali resistance, and aging resistance. At the same time, it also has a wide range of pore sizes, a tortuous pore distribution, excellent permeability and filtration performance.

application

1. Filtering of dams and slope protection in hydraulic engineering, isolation and anti-seepage of channels;

2. Basic isolation, filtration, and drainage of highways, railways, and airport runways, as well as reinforcement and drainage of soil slopes, retaining walls, and road surfaces;

3. Soft foundation treatment for port engineering, reinforcement and drainage of beach embankments, harbor docks and breakwaters;

4. Isolation and anti-seepage of landfills, ash dams in thermal power plants, and tailings dams in mines;

5. Polyester filament spunbond needle punched geotextile has been widely used in the field of infrastructure construction and gradually applied to a wider range of fields.

Project/Specification | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | notes |

Deviation in unit area quality (%) | -6 | -6 | -6 | -5 | -5 | -5 | -5 | -5 | -4 | -4 | -4 | — |

Thickness mm ≥ | 0.8 | 1.2 | 1.6 | 1.9 | 2.2 | 2.5 | 2.8 | 3.1 | 3.4 | 4.2 | 5.5 | — |

Width deviation% | -0.5 | — | ||||||||||

Breaking strength KN/m ≥ | 4.5 | 7.5 | 10.0 | 12.5 | 15.0 | 17.5 | 20.5 | 22.5 | 25.0 | 30.0 | 40.0 | Vertical and horizontal directions |

Fracture elongation rate ≤ (%) | 48-80 | |||||||||||

CBR breaking strength Kn ≥ | 0.8 | 1.4 | 1.8 | 2.2 | 2.6 | 3.0 | 3.5 | 4.0 | 4.7 | 5.5 | 7.0 | — |

equivalent aperture 090095)mm | 0.07-0.2 | — | ||||||||||

Vertical permeability coefficient cm/s | Kx(10-1-10-3) | K=1.0-9.9 | ||||||||||

Tear strength Kn ≥ | 0.14 | 0.21 | 0.28 | 0.35 | 0.42 | 0.49 | 0.56 | 0.63 | 0.70 | 0.82 | 1.10 | Vertical and horizontal directions |